Tonight I am sharing a shawl embellished with Teneriffe Lace

and block printing that I made ready for Gina’s Lace show on Hochanda TV

tomorrow at mid day (29

th Oct 2019 on Freeview Channel 85 or watch

catch up online via their website).

Gina has a button show at 4pm too where she will be bringing lots of her

fabby historical button making kits, books and DVDs. Both shows are a must to

see if you love textile embellishments, trims and passementerie.

Materials:

- Lime green crochet cotton no.3 (Delfino – Filo Di Scozia)

- Lilac DMC Mouline Cotton (like a standard 6 strand embroidery floss but on a

large spool)

- Sewing thread and needle (lime green)

- Lime green cotton triangular shawl (made from quilting cotton) with sides

measuring approx. 1m (I overlocked the edges using matching thread to prevent

fraying)

- Teneriffe

Lace Starter Kit Loom 3 (Gina B Silkworks)

- Teneriffe

Lace Vandyke Border Loom set (Gina B Silkworks)

- Fabric glue (optional)

- Thick dense foam mat (such as provided with Gina’s Total

Trimmings Table) or upholstery foam (optional if wanting to use pins for

stretching the web)

- Laundry starch spray (optional)

- Decorative Indian wooden printing block and

foam printing mat (Colouricious). The one I chose from

my stash was approx. 9.5cm square with space in the centre to add the lace

floral motifs

- Setacolor Opaque (Spring Green, Raspberry and Parma Violet) and Deka Perm

(Opaque White) fabric paints

- Kitchen sponge and paint tray

- Iron

How to do it:

Gina’s loom kits provide general instructions for stretching the web,

darning, reverse backstitch and knotting etc.

Note: The hardest part to get right is the Teneriffe Lace Knot which

holds it all together. Get this wrong and your lace won’t hold together properly

when you remove it from the loom. Should this happen, don’t despair, do what I

did with my first lace attempts and glue it to a card or a mixed media canvas.

Ha ha.

There is a great

beginners video

from Gina to help with this.

I spent quite some time developing the lace pattern by quite

a lot of experimenting, undoing and redoing until I was happy with the result.

Don’t be afraid to play. Gina has also provided some easy starter lace borders

in the instructions so you could try these first and make up a couple of

smaller projects first.

The Border Lace:

Whenever thread ends were tied and finished, or working

threads joined with knots, I added a small dab of clear drying fabric glue for

extra security. This is optional but I thought it would ensure no loosening of

thread ends, particularly during lots of wear and washing etc.

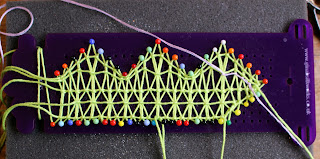

Starting: I stretched

the web on the Vandyke Border Loom leaving a long end at the start and keeping

the ball in place on the left hand side (to avoid making joins as the border is

continued). Here I have wrapped the thread end a couple of times around the

loom end to hold the tension in place.

I made an angle on the first end so that it would continue

on the shape of the shawl corner. The pins were placed on a diagonal and

threads held together by K 2e (knotting 2 threads to hold).

Note: When

working some of the bigger projects I prefer to use pins to hold the web rather

than lacing with waste thread. It is a little less portable in this method but

much quicker to stretch the web.

Row 1: I worked a

row of sc (scalloped edge by k 2e to create small anchored loops) along the

bottom edge, joining in a new thread as required.

Row 2: Next I

worked a row of K 2e (keeping the pairs of threads in alignment with the first

bottom row of knots) along the centre of the lace band.

Note: For each

row I joined a new length of yarn. Once worked this was loosely wrapped and

tied (to prevent tangling) and kept on the left hand side, ready to work the

next section of the lace as the lace is moved on along the loom.

Row 3: I then

worked a row of sc along the top edge. See how the threads now separate to give

a lacy effect. Again I joined a new thread for this row.

Row 4: A row of k

4e (4 threads knotted together such that the groups of knotted threads aligned

with the peaks and troughs of the top edge) was worked in the centre of the

bottom straight border section. This opened out the threads into a pretty lace

design.

Row 5: A row of *k

2e (x3), k 4e (x1), K 2e (x3)* was repeated along the top border. The 2e knots

were worked just below the knots on the sc edge and the 4e knots were worked

about half way down the space. This created a nice section with 7 little spaces,

ideal for darning (weaving) in the next row.

Row 6: Next I

joined in the lilac thread. To start I knotted just under the threads of the

previous row until reaching the centre of the 7 space section.

Row 6 continued: The

7 space section was progressively darned (pdt) for 8 rounds. The thread was

taken under 1, over 2, under 2, over 1, under 1, then over 2 and under 1 to

complete the first round (starting at the top left hand side single thread). As

the rounds are worked the weave goes in the opposing over/under direction

naturally (as there is an odd number of thread groups/spaces).

When 8 rounds were complete the thread was taken under the

first thread bar again before moving along to the left with knotting.

Full row 6 repeat: *k 2e (x3), k 4e (x1), pdt (x8) in the

round, u 1e, K 2e (x3)* repeated along the top border.

These 6 rows form the pattern repeat for the straight border

sections. The straight knotting rows are quite quick to work but the darning

does take a little longer. Well worth it though I think.

The lace was then removed from the loom ready to work the

next section.

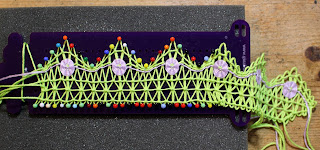

The first few loops were replaced onto the end of the loom

and the next section of web was stretched ready to work. Here you can see the

ball kept in place (keeping the web continuous without thread joins). The

working threads were loosely tied for each row (keeping them separate, tying in

a new length as required).

The next section of lace was then worked as given above.

Again the lace was moved along as each section was

completed. I was so excited to see it grow.

I had calculated that I would need 25 little peaks to fit

along the sides of my scarf before needing to turn the corner (the space between

each peak being approx. 4cm and the sides of my scarf being approx. 1m).

Note: The lace

does pull in slightly when removed from the loom (the amount will vary

depending on stitches used). Bear this in mind and check that the length of your

lace is OK before turning the corner (particularly on a large project).

As with the straight border I pinned the first few loops of

lace onto the corner loom and laid out the pins ready to stretch the web.

I stretched the web on the first half of the corner then

spent some time thinking – how was I to make a corner pattern that would

continue the straight sections nicely? This took me some time – ha ha.

The threads on the corner diagonal of the web need to be

interlocked. I therefore broke the thread and stretched the next section of the

web, threading up the needle and passing through the loops of web on the

diagonal (Gina explains this in her instructions). I then tied the thread end

back to the ball end of thread.

I had a lot more thinking here about where to go next – tee hee.

I worked rows 1-4 as previously adding extra knots where the

diagonal threads crossed to make sure that the intersection was well anchored.

I then started row 5 and had a lot more thinking on the

corner section. The full peak sections on either side were to be completed in

the same pattern but I wasn’t sure what to put in the corner. I liked how I had

continued the bottom border section keeping the design cohesive.

Continuing row 5: After

the first 3 knots (worked as per the normal pattern) I then moved to the centre

and knotted up one side of the diagonal and back down the other (k 2e). This

anchored all the threads well on the upper part of the diagonal. Note that I

split the thread groups (see above where the outer threads are grouped together

on the web) to make a lacy effect. I hope that this makes sense. It is

difficult to explain – sorry.

Continuing row 6:

I worked the first peak in the same way as usual then worked 3 knots up the

outer edge (as in a normal row start). See picture below.

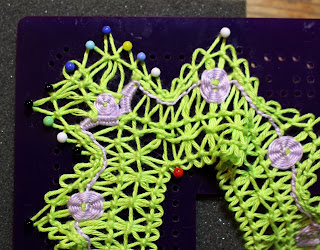

The corner was completed by weaving 2 little ‘leaf’ sections

across the diagonal threads. Starting at the tip I wove down to the middle

(filling the space), then up the other side and then 3 knots were worked down

to the trough section as normal. The next section being worked as per the normal

pattern.

The lace was then removed from the corner loom and replaced

back onto the border loom ready to work up the other side (as shown above).

Here you can see the full length of one border and the

corner turned ready to work the other side. I got very excited here – ha ha.

Here is a close up where you can see the corner more

clearly.

Although fairly pleased I still wasn’t completely happy with

it (more thinking! Ha ha).

I took the lace back off the border loom and quickly

anchored it back onto the corner. With a new length of thread I added a little

circle of weaving (over 5 groups of thread). I was happier with the result now.

I continued with the usual pattern until the last section.

Here I again wanted a diagonal finish on the end.

Here I have shown the corner of the scarf so you can see

what I mean. The loom is not designed to make diagonal ends as I am wanting so

you can see one of the pins is slightly out of alignment here. This loop is adjusted

when knotting (see below).

You can see here that the misaligned pin is removed as the

last knot is worked on row 2 (the ball thread end then being tightened up). The

other pins sit on the diagonal path OK.

Happy with my finished corner – finally – ha ha.

Block Printing:

Next I wanted to create a pretty block printed border.

I used the lime green paint on the outer part of the block

(applying with kitchen sponge).

I mixed a little of the Raspberry and Violet with quite a

lot of White to create a colour that matched well with my lilac thread. This

mix was sponged onto the inner section of the block for printing.

The scarf was laid onto the foam base for printing. This

provides a little cushioning against the solid wood block ensuring that the

detail prints well.

Oooh yummy print.

Oooh – I was a happy bunny. I left the paint to fully dry

overnight then heat fixed by ironing on the reverse on a cotton setting.

I then hand stitched on the lace border easing it to fit. In

order to provide a little stretch and ease I used a slight zig zag when

stitching (this allows a little stretch without popping of the thread). Next I

sprayed with starch and ironed. This smoothed any slight lumps & waves that

formed after attaching the lace and also stabilised the lace nicely.

I was so chuffed with how the lace border and printing

looked.

The Floral Daisy Motifs:

Next I worked 16 small daisy motifs on loom 3.

I stretched the web on the smallest circle and lime thread to

create 16 edge loops (i.e. total of 32 threads crossing the central section).

I then worked DD (double darning 2e) for 2 rows in the

centre to neaten up the crossing threads etc. On the second row I offset the

threads darned in the first row (as in weaving).

I then worked Revs (2) for 3 rows: Reverse backstitch over 2

threads. Ensuring that the threads from adjacent ‘loops’ were grouped together

to form the outer ‘petal’ loops. Note: The side facing you is the back of the

work.

Then I worked K 2e for 1 row: Knotting 2 threads together to

secure groups of threads creating the long scalloped edge loops that make the

petals.

These little flowers would make great earrings or could be

joined to make a lovely necklace. In fact it was these that gave me the idea

for my black lace earrings blogged in my previous post earlier today.

Finally I finished the shawl by sewing the little daisies

into the centre of the block printed motifs.

I hope that you like my lace shawl. Teneriffe Lace is

definitely a ‘slow craft’ akin to knitting or cross stitch, don’t expect quick

results. This project took me around 25 hours to make! Take your time and enjoy

the process xxxx.